Why is roaster drum speed so important

Hot air and coffee roaster drum speed

In drum roasting, heat transfer is mostly through hot air convection and a little through conduction. the air roasted coffee tends to have a better sweetness, cleanness, more even heat apply.

However, the single hot-air roasting method may results in incomplete development of coffee beans since the rapid heating may lead to a case that although the outer bean is well-roasted while the inner bean is still uncooked.

If just use a simple "direct fire roasting", the roasting may be uneven due to the factors of size firepower, heat control, etc. or even burnt and bitter taste.

Thanks to the technical innovation, "semi-hot air and semi-direct fire" are combined into each other, the drum roaster has more flexibility control on airflow and firepower, etc.

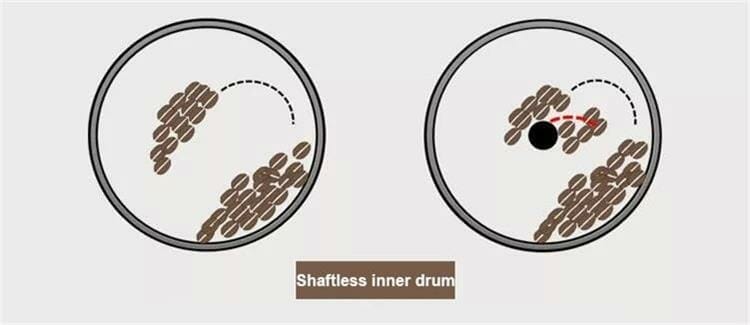

To take the advantages of the "semi-direct fire semi-hot air" roaster, it is necessary to have a core function "roaster drum speed adjustment" and the application of the shaftless inner drum, so that the beans are not interfered by the central axis, reaching the optimal trajectory.

- Roaster drum speed one

- Roaster drum speed two

- roaster drum speed three

- Special designed inner drum heat transfer.

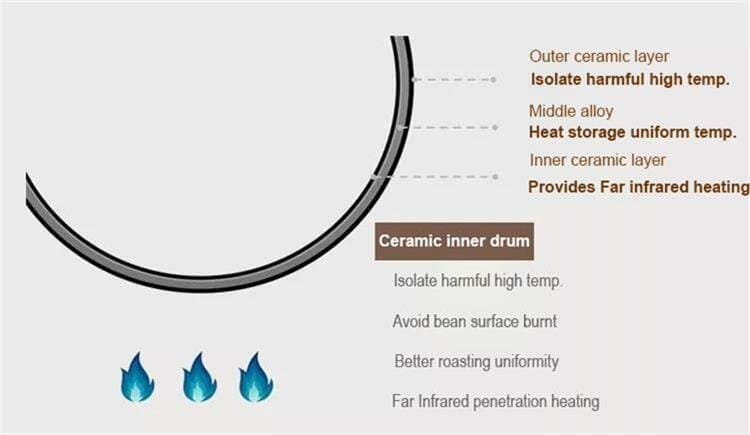

- Inner drum material selection

At a higher speed, presenting the movement of beans in a full circle of rotary drum. Each bean is evenly heated during the motion trail.

When lowering the drum speed, the motion path of coffee beans is also changing.

At a lower drum speed, showing the path of motion. if not full-load roasting, your sampling spoon may be empty if the amount of beans is small.

Inner drum and drum mixing blades

A good stirrer design allows the beans to move in a regular path and heat evenly, ensuring that the coffee beans have a higher heat transfer ratio and a longer time to stay in the air and evenly heat distribution.